(Part II of “Promise, Pragmatism & Pathways for Indian Manufacturing”)

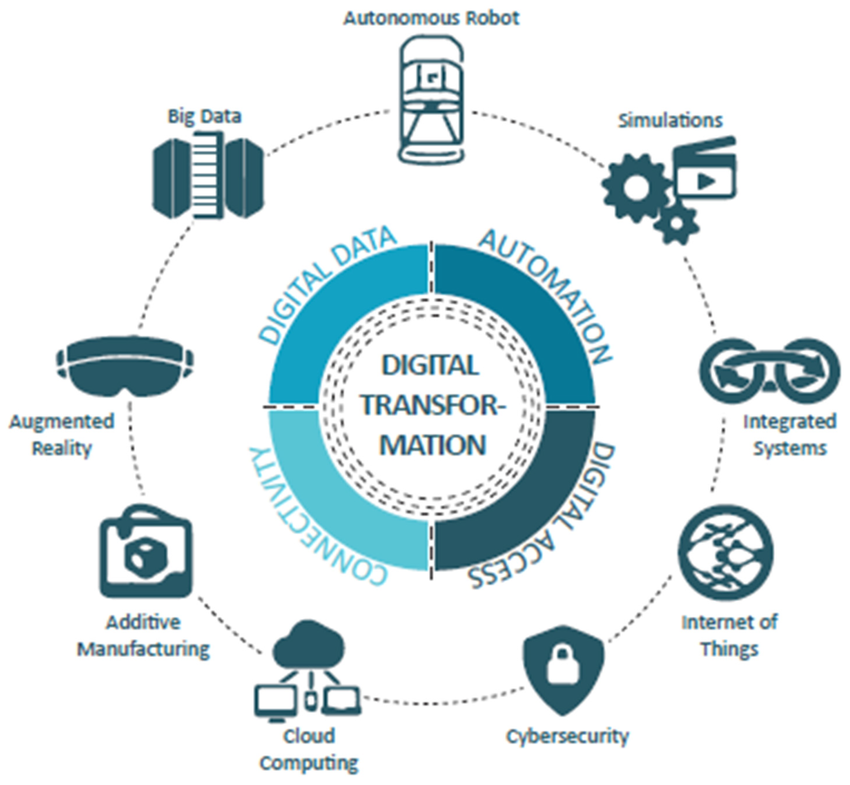

If Industry 4.0 was once a buzzword, it has now matured into a measurable differentiator a quiet revolution determining who will lead the next decade of global manufacturing. Yet, in India, the divide between those who are “digitally active” and those who are “digitally intelligent” is widening fast.

The reality most Indian factories are data-rich but insight-poor. Machines generate terabytes of information through PLCs, drives, and SCADA systems, yet less than 5% of that data is ever captured, contextualized, or analyzed in real time.

The challenge is no longer data acquisition — it’s data orchestration.

The Global Context: Where India Stands

Germany’s “Industrie 4.0” initiative, Japan’s “Society 5.0,” and China’s “Made in China 2025” have already demonstrated what synchronized digital transformation looks like. Their manufacturing systems operate as cyber-physical ecosystems, where sensors, software, AI, and humans continuously communicate to optimize productivity, reduce waste, and drive precision.

In contrast, Indian factories are evolving in pockets an isolated IoT pilot here, a paperless dashboard there — but rarely an integrated architecture.

The absence of a unified digital thread connecting Machine → Process → People → Business is the root constraint preventing scalability.

Decoding the Architecture of Industry 4.0

To understand implementation, one must break Industry 4.0 down to its five technical layers:

Physical Layer – Machine Connectivity

Involves IoT gateways, edge devices, and retrofit sensors (vibration, temperature, load, power, and speed).

Legacy machines (without inbuilt OPC-UA or MQTT protocols) can be retrofitted using Modbus TCP converters or RS-485 gateways.

Example: A 15-year-old CNC or lathe can start streaming data to the cloud within a week at ₹40,000–₹60,000 per node.

Data Layer – Integration & Storage

Data is extracted via MQTT/OPC-UA brokers and stored in time-series databases.

Middleware solutions like Thing Worx, Kepware, or Node-RED convert raw tags into meaningful production variables (uptime, OEE, cycle time).

For SMEs, open-source stacks (Influx DB + Grafana + MQTT Broker) can be deployed at minimal cost.

Analytical Layer – Intelligence & Prediction

AI and ML models analyze process parameters, quality metrics, and consumption patterns.

Predictive maintenance algorithms use vibration spectral analysis and regression trees to forecast machine failure.

Quality analytics use computer vision and deep learning for defect classification — now accessible even through smartphone-grade cameras.

Execution Layer – MES & ERP Integration

MES (Manufacturing Execution System) forms the operational bridge between shopfloor and business applications.

Integrating MES data with ERP (SAP, Oracle, or local ERP systems like Merci Global ERP) ensures traceability from order to invoice.

This layer enables “Closed-Loop Manufacturing” where business changes trigger process optimization in real time.

Visualization Layer – Decision Cockpit

Dashboards built on Grafana, Power BI, or custom BI tools like PERCIV X translate real-time data into visual insights.

CXOs can view live OEE, machine status, and energy utilization on web or mobile, enabling remote factory management a reality already embraced in German Tier-2 manufacturing.

The Technical Pain Points: The Indian Reality Check

Data Silos: Machines, quality labs, maintenance logs, and ERP systems still operate as disconnected islands.

Bandwidth & Infrastructure: Many plants struggle with unreliable Wi-Fi, legacy LANs, and non-industrial-grade routers.

Human Integration: Operators resist digital tools due to lack of training or interface simplicity.

Cybersecurity: With increasing device connectivity, ransomware and data theft are legitimate threats.

ROI Uncertainty: Lack of baseline data makes it difficult to quantify savings pre-implementation.

These are not abstract issues they are everyday manufacturing truths. But the counter to each challenge is engineering logic, not marketing promise.

Solution Framework: The 4D Approach for Indian MSMEs

1. Diagnose → 2. Digitize → 3. Derive → 4. Drive

Diagnose: Conduct a Digital Maturity Assessment (DMA) mapping current equipment connectivity, software landscape, and process maturity.

Digitize: Begin with retrofitting and data acquisition not replacing existing assets. The goal is visibility, not reinvention.

Derive: Deploy analytics to translate raw data into actionable insights (OEE, energy intensity, quality deviation).

Drive: Integrate ERP/MES to enable real-time decision-making production planning, maintenance scheduling, and quality control.

This framework aligns perfectly with Lean + Digital philosophy, delivering tangible benefits within 3–6 months.

ROI in Numbers: Measured, Not Imagined

| Function | Digital Intervention | Typical Investment (₹ Lakhs) | ROI Period | Impact |

|---|---|---|---|---|

| Machine Downtime Tracking | IoT Sensors + Cloud Dashboard | 2–3 | 6 months | 10–15% increase in machine uptime |

| Energy Optimization | Smart Energy Meters + Analytics | 3–5 | 8 months | 8–12% energy savings |

| Predictive Maintenance | Vibration + AI Analytics | 4–6 | 9 months | 15–20% reduction in maintenance cost |

| Digital Quality Management | Vision System + AI | 5–7 | 12 months | 25–30% reduction in rejections |

These are real numbers from Indian mid-sized manufacturing units in automotive, textile machinery, and process industries.

The Global Benchmark – India’s Catch-Up Curve

In Germany and Japan, digital twin simulation and autonomous process correction are standard. A production line can self-adjust temperature, pressure, or feed rate based on AI recommendations.

India is catching up companies like Bharat Forge, Godrej Aerospace, and SRF have initiated large-scale IIoT rollouts.

But the transformation must now cascade downward into Tier-2 and Tier-3 suppliers, where the real volume of Indian manufacturing resides.

The government’s Digital MSME Scheme and Samarth Udyog Bharat 4.0 centers are strategic moves, but execution partnerships with private tech firms, ERP providers, and system integrators will define success.

Smooth Execution: The CXO Playbook

Start with Business KPIs, not Technology: – Identify which metric matters most energy, yield, downtime, or quality and design digital projects around it.

Choose Scalable Tech: – Cloud-first, open-protocol-based systems prevent vendor lock-in.

Upskill Continuously.

Create Digital Champions within the organization engineers trained in both operations and analytics.

Integrate Finance Early: – Link digital metrics with financial outcomes; show how OEE gains translate into rupees saved.

Secure Your Data: – Use industrial-grade firewalls, encrypted MQTT brokers, and routine cybersecurity audits.

The Next Leap: From Connected to Cognitive Manufacturing

Industry 4.0’s next phase, Industry 4.5 is already emerging, where machines don’t just talk, they think.

AI models at the edge will make autonomous decisions; blockchain will assure product traceability; 5G-enabled factories will operate with sub-second data latency.

For Indian manufacturing, this isn’t a distant dream. It’s an impending reality provided execution remains pragmatic, modular, and data driven.

Conclusion: The New Industrial Dharma

The true spirit of Industry 4.0 is not automation it’s augmentation. It doesn’t replace human intelligence; it amplifies it. It’s about synchronizing the rhythm of man, machine, and mind creating a factory that learns, adapts, and evolves.

For Indian MSMEs and industrial houses, the path forward is clear “Digitize with discipline, automate with awareness, and measure with meaning” .

The world no longer rewards the biggest it rewards the most intelligent.